CO2 graving

What is CO2 Graving?

CO2 graving is a fascinating and versatile print technique widely used in the printing and promotional gifts world. It involves using a CO2 laser to etch designs onto various materials, creating intricate and durable markings. This method has become increasingly popular due to its precision and ability to personalize a wide range of products.The history of CO2 graving dates back to the late 20th century when CO2 lasers were first introduced. These lasers were initially used in industrial applications but quickly found their way into the printing and engraving sectors. The basic process of CO2 graving involves directing a focused beam of CO2 laser light onto the surface of a material. This beam vaporizes the material in its path, leaving behind a permanent mark.

To begin, the design to be engraved is created using computer software. This design is then sent to the CO2 laser engraver, which interprets the digital image and guides the laser beam accordingly. The laser's intensity and speed can be adjusted to achieve different depths and effects, allowing for a high degree of customization. The result is a precise and clean engraving that stands out for its detail and durability.

Essential Tools and Materials for CO2 Graving

To perform CO2 graving, several key tools and materials are required. The primary tool is the CO2 laser engraver itself, a machine equipped with a CO2 laser tube and a movable platform to position the material. Additionally, a computer with design software is essential for creating and sending designs to the engraver. Common materials used in CO2 graving include wood, acrylic, glass, leather, and various metals. These materials are chosen for their ability to react well to the laser, producing clear and lasting engravings.

Applications and Examples of CO2 Graving

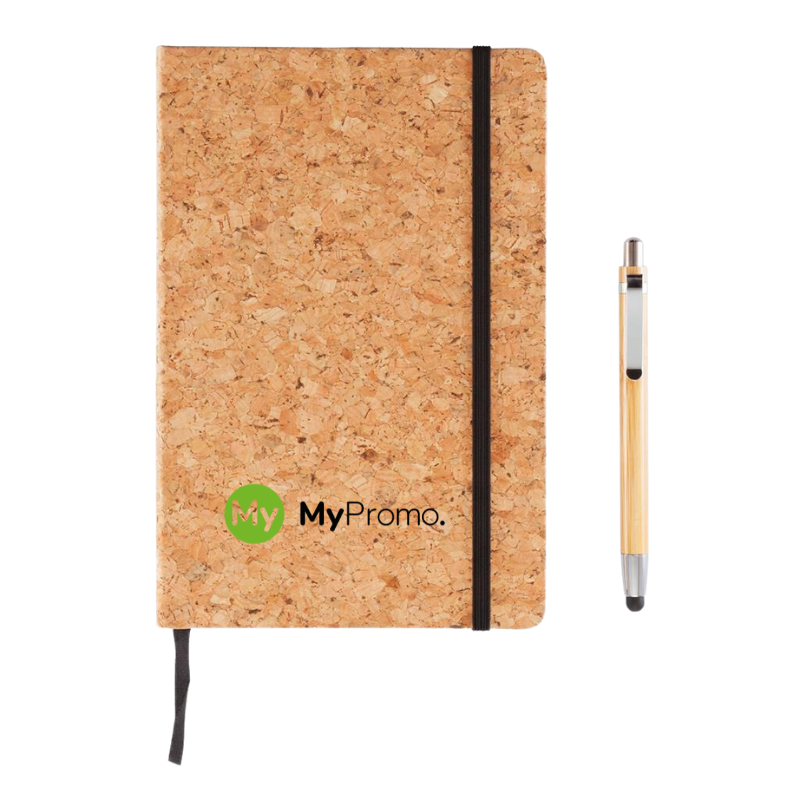

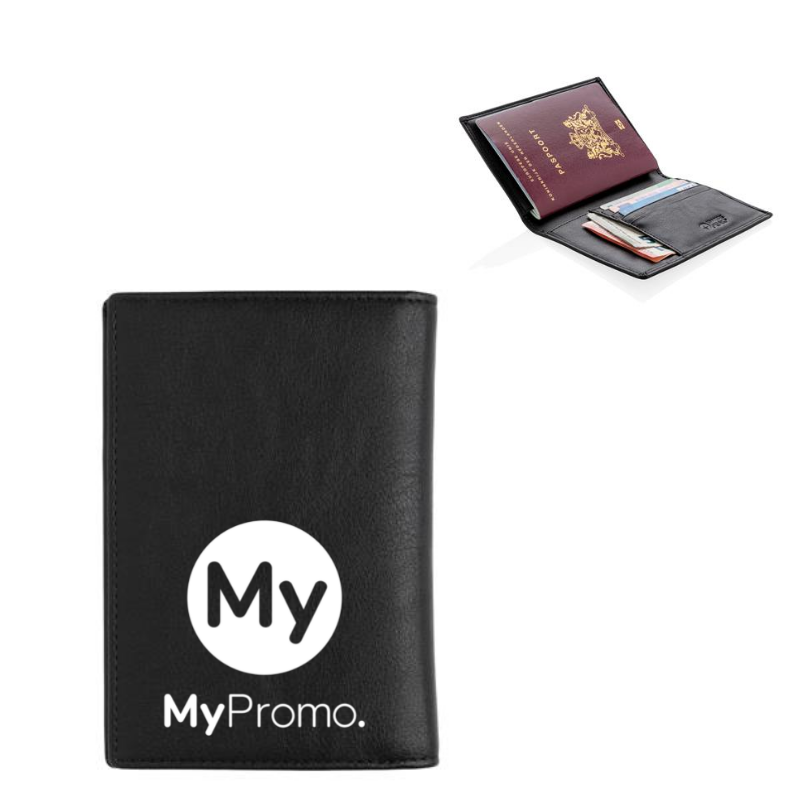

CO2 graving is incredibly versatile, making it suitable for a wide range of applications. It is commonly used to personalize promotional products such as personalized keyrings, pens, personalized trophies, and plaques. For instance, a company might use CO2 graving to etch their logo onto a series of corporate gifts, creating a professional and lasting impression. Another notable application is in the creation of customized gifts, such as engraved jewelry or personalized photo frames, which add a unique and personal touch to special occasions.

Advantages of CO2 Graving

One of the main advantages of CO2 graving is its precision. The fine laser beam allows for detailed designs that are difficult to achieve with other engraving methods. This technique also offers great versatility, as it can be used on a wide variety of materials. Additionally, CO2 graving is a non-contact process, which means it does not wear down or damage the material being engraved. The results are permanent and highly resistant to wear, making it ideal for items that need to withstand frequent handling.

Comparing CO2 Graving with Other Print Techniques

Compared to other print techniques, CO2 graving stands out for its ability to create intricate and permanent designs. Unlike ink-based printing methods, CO2 graving does not fade over time and is resistant to smudging. While screen printing and pad printing are suitable for producing large quantities of items with the same design, CO2 graving excels in creating highly customized, one-off pieces. However, it is worth noting that CO2 graving can be slower and more expensive than some other methods, particularly for large-scale production.

Challenges and Limitations of CO2 Graving

Despite its many advantages, CO2 graving does have some challenges and limitations. The initial cost of purchasing a CO2 laser engraver can be high, which might be a barrier for small businesses. Additionally, the process can generate fumes and debris, requiring proper ventilation and safety measures. Some materials, such as certain plastics, may not react well to CO2 lasers and can produce toxic fumes. Therefore, it is crucial to select appropriate materials and maintain a safe working environment.

In conclusion, CO2 engraving is a highly effective and versatile print technique that offers precision, durability, and customization. While it has some challenges, the benefits make it a popular choice for personalizing promotional products and creating unique, high-quality items.

| Aspect | Description |

|---|---|

| Definition | A print technique using a CO2 laser to etch precise designs on various materials. |

| Origins | Emerged in the mid-20th century with the advent of laser technology, initially used for industrial applications. |

| Process | Involves creating a digital design, loading it into a laser engraving machine, and using a CO2 laser beam to vaporize the material's surface following the design. |

| Essential Tools | - CO2 laser engraving machine - Computer with design software |

| Materials | - Wood - Acrylic - Glass - Leather - Certain metals |

| Applications | - Promotional items - Personalized gifts - Company logos on wooden plaques - Customized glassware - Personalized leather goods |

| Examples | - Engraved acrylic awards - Bespoke wooden coasters - Customized metal pens - Engraved glass trophies - Wooden keychains - Leather accessories |

| Advantages | - High precision - Permanent and wear-resistant engravings - Versatile across various materials - Non-contact process reducing wear and damage |

| Comparison | - Compared to screen and pad printing, CO2 engraving excels in precision and durability. - Ideal for intricate designs and high-end products. |

| Challenges | - Higher initial investment - More time required for setup and design preparation |

What is CO2 graving?

CO2 graving is a popular print technique used for creating precise and intricate designs on various materials. This method leverages a high-powered CO2 laser to etch patterns, logos, or text onto surfaces, making it an invaluable tool in the printing and promotional gifts industry.

How does the CO2 graving process work?

The process of CO2 graving begins with creating a digital design, which is then loaded into the laser engraving machine. The CO2 laser emits a concentrated beam of light that vaporizes the material’s surface, following the design’s path. This results in a precise and permanent engraving. The depth and intensity of the engraving can be controlled by adjusting the laser’s power and speed, allowing for various effects and finishes.

What materials are suitable for CO2 graving?

Materials suitable for CO2 graving include wood, acrylic, glass, leather, and certain metals. Each material interacts differently with the CO2 laser, offering unique finishes and possibilities. For instance, wood and acrylic can produce detailed and high-contrast engravings, while glass and leather require more precision and care to achieve the desired results.

What are some common applications of CO2 graving?

CO2 graving is widely used in the production of promotional items and personalized gifts. Common applications include engraving company logos on wooden plaques, customizing glassware with intricate designs, and personalizing leather goods such as wallets and notebooks. Notable examples include engraved acrylic awards, bespoke wooden coasters, and customized metal pens.

What are the advantages of CO2 graving?

One of the main advantages of CO2 graving is its ability to produce highly detailed and accurate designs. This precision is particularly beneficial for intricate logos and fine text, which might be challenging to achieve with other printing techniques. Additionally, CO2 engraving is a non-contact process, meaning there is no physical wear on the materials, resulting in a cleaner finish and less risk of damage.