Digital label

What is digital label?

A digital label refers to the modern method of printing labels using digital printing technology. This technique allows for high-quality prints directly from digital files, bypassing the traditional methods of plate printing. Digital labels have become essential in the printing and promotional gifts world due to their flexibility in design and rapid production capabilities. Historically, label printing required extensive setup, which was not cost-effective for short runs. With the advent of digital printing technology in the late 20th century, it became possible to produce small quantities of labels efficiently, revolutionizing the packaging and marketing industries.

Essential tools and materials in digital label printing

Creating digital labels requires specific tools and materials to ensure high-quality output. The primary tool is the digital printer itself, which is specifically designed to handle various printing tasks and material sizes. Along with the printer, high-quality inks are essential for achieving vibrant colors and sharp details. Substrates, or the materials onto which the images are printed, vary widely from paper and synthetic materials to more specialized media like metallics or transparent films. Software for graphic design and printer management also plays a critical role in the digital label printing process.

Applications and examples in the promotional industry

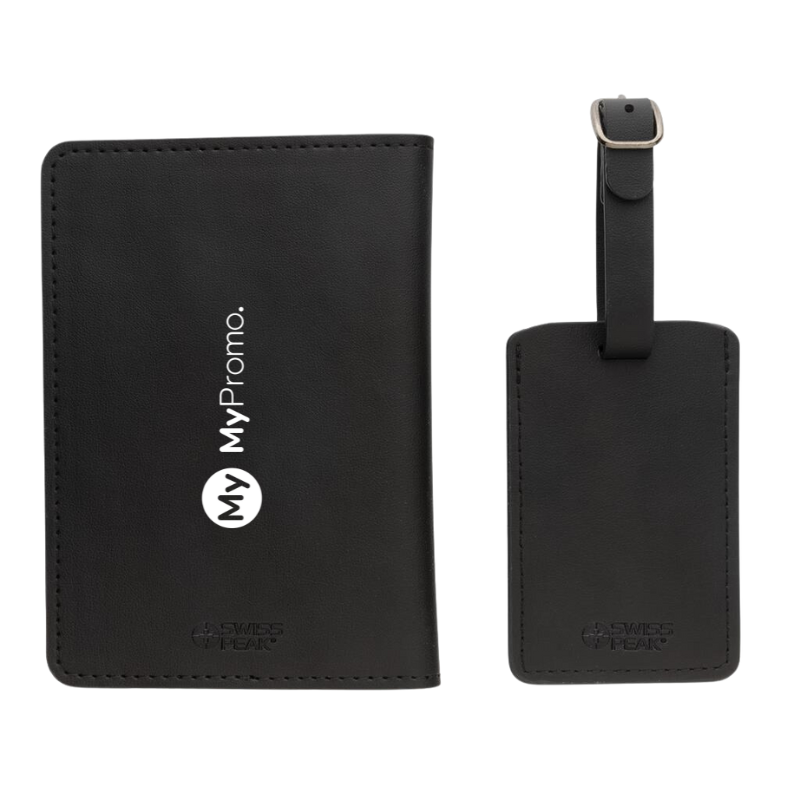

Digital labels are versatile and can be applied to a wide range of promotional products. For example, custom labels are frequently used on personalized water bottles, electronics like personalized USB sticks, and office supplies such as personalized folders. This printing technique allows for high-resolution images and texts to be added to items, which can be particularly useful for branding and promotional campaigns.

Advantages of digital label printing

The advantages of using digital label printing are significant, particularly for businesses looking for efficient, high-quality, and customizable printing solutions. Digital labels offer exceptional print quality with vibrant colors and clear, crisp details. The setup for digital printing is quicker and less expensive since it doesn't require plates. Moreover, digital label printing allows for on-demand printing, low minimum quantities, and easy updates to designs, which is ideal for time-sensitive promotions and the ability to respond quickly to market demands.

Comparing digital label printing with other techniques

When compared to traditional printing techniques such as offset or flexography, digital label printing stands out for its speed and flexibility. Traditional methods often require longer setup times and are not cost-effective for small runs. In contrast, digital printing is ideal for shorter runs and highly customized projects. However, for extremely high-volume tasks, traditional methods might still be more economical due to their faster printing speeds once set up.

Challenges and limitations of digital label printing

Despite its many benefits, digital label printing does have limitations. The cost per label is generally higher than traditional methods when it comes to very large volumes. Additionally, the range of substrates and special inks (such as metallic or fluorescent inks) can be more limited in digital printing compared to methods like screen printing. Ensuring color accuracy and managing color consistency across different batches can also pose challenges, particularly when trying to match colors used in other corporate branding materials exactly.

| Material Type | Characteristics | Suitability | Common Uses |

|---|---|---|---|

| Paper | Cost-effective, versatile | High | Standard product labels, shipping labels |

| Vinyl | Durable, flexible, water-resistant | High | Outdoor applications, durable goods |

| Polyester | Tear-resistant, high-quality | High | Industrial applications, harsh environment labels |

| BOPP | Oil and water-resistant, strong | High | Food and beverage labels, bath and body products |

| Static Cling Vinyl | Reusable, sticks without adhesive | Moderate | Window decals, temporary promotional stickers |

What is a digital label?

A digital label refers to a label produced using digital printing technology, where digital images are printed directly onto label material without the need for printing plates. This method allows for high-resolution, full-color labels with quick turnaround times and lower costs for small to medium print runs.

How does digital label printing work?

Digital label printing works by transferring digital images directly onto materials using inkjet or laser printers. The process involves creating a digital file of the label design, which is then sent to a digital printer. The printer applies inks or toners onto the label material to reproduce the image exactly as designed.

What are the advantages of digital label printing?

Digital label printing offers several advantages, including:

- Flexibility in design changes: Easily update designs without the need for new plates or setup costs.

- Cost-effective for small runs: Ideal for small to medium quantities because it eliminates the costs associated with traditional plate-making.

- High-quality prints: Produces sharp, clear labels with vibrant colors.

- Quick turnaround: Faster production times since there is no need to create plates.

- Customization: Allows for easy customization and variable data printing such as barcodes and numbering.

What types of materials can be used for digital labels?

Digital labels can be printed on a variety of materials depending on the printer type and purpose of the label. Common materials include paper, polyester, polypropylene, and vinyl. These materials can be finished with gloss, matte, or satin laminates to enhance durability and visual impact.

Are digital labels environmentally friendly?

Digital labels can be more environmentally friendly compared to traditional labels due to several factors:

- Less waste: Digital printing produces fewer waste materials because there's no need for plates and less setup material is required.

- Energy efficiency: Digital printers typically use less energy compared to traditional printing presses.

- Reduced chemical usage: Digital printing uses fewer harsh chemicals and solvents, which can be beneficial for the environment.